Brazed Plate Heat Exchanger beer to water heat exchanger nanjing bang win

Product Description

Professional Plate heat exchanger Factory With 20 years Experience

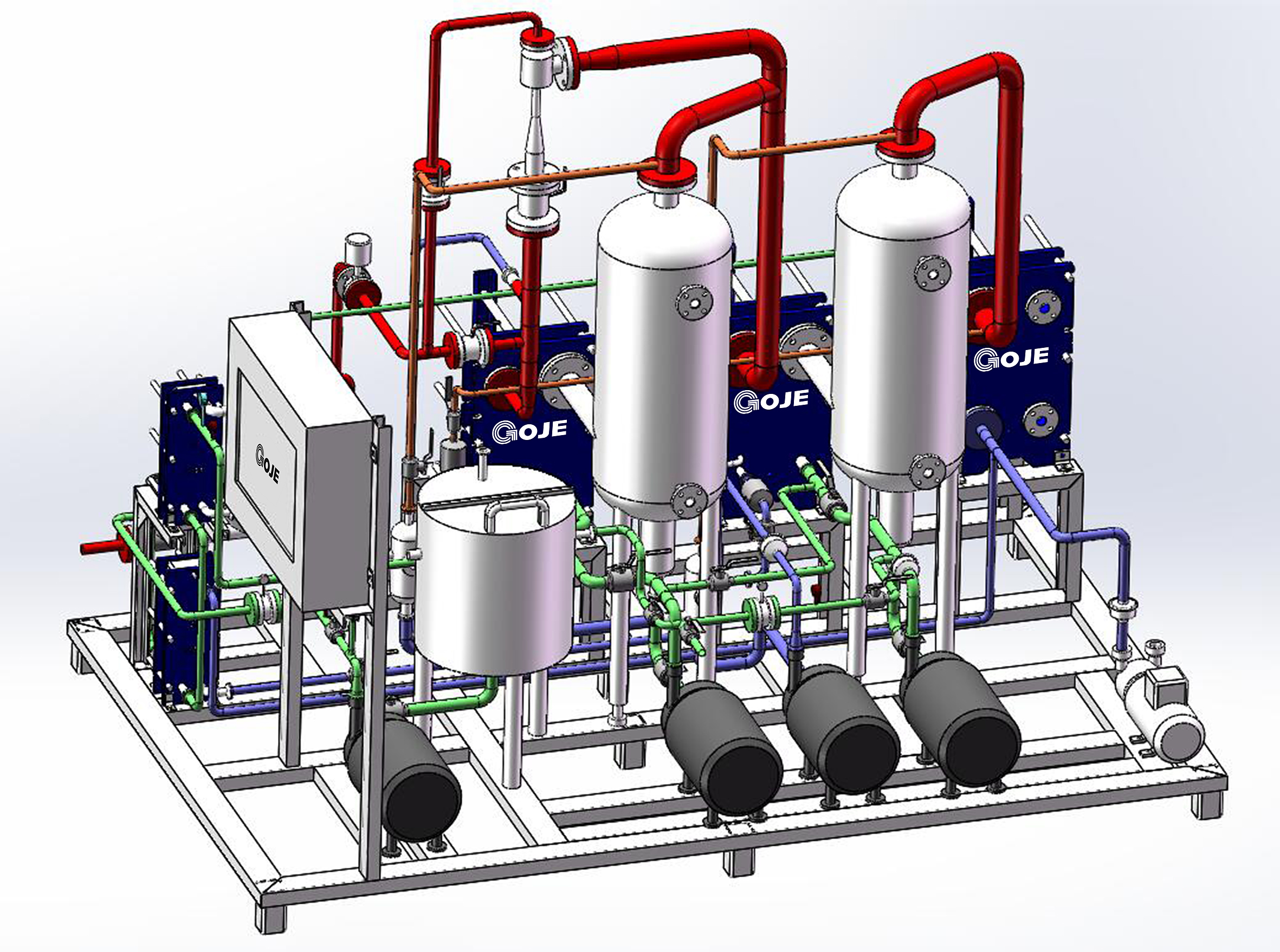

ONE-STOP Heating Transfer Solution For You

Design different plate heat exchanger for your usage

(Metallurgy, food, petrochemical, pharmaceutical, beverage, wastewater, refrigeration etc..)

More About Our PHEs

1. Frequently Used PHE types

Plate heat exchanger is an ideal equipment for heat exchange between liquid and steam. The utility model has the advantages of high heat exchange efficiency, small heat loss, compact and light structure, small floor area, wide application, long service life, etc. Under the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of the tube heat exchanger, the floor area is one third of the tube heat exchanger, and the heat recovery rate can be as high as 90%.

Stainless Steel PHEs

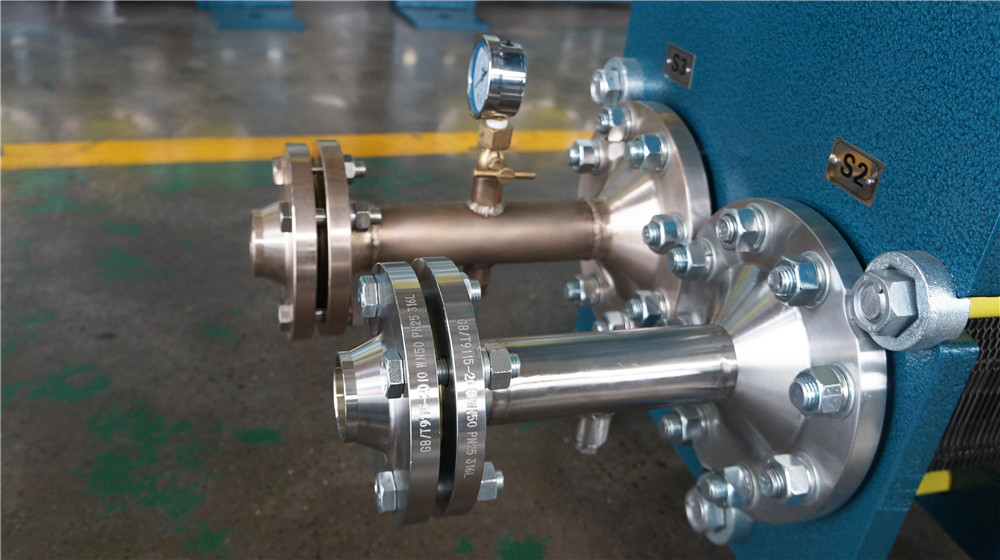

Widely used in food, beverage, alcohol, dairy, pharmaceutical and chemical industries.2. Normally Used Connections

Project Case

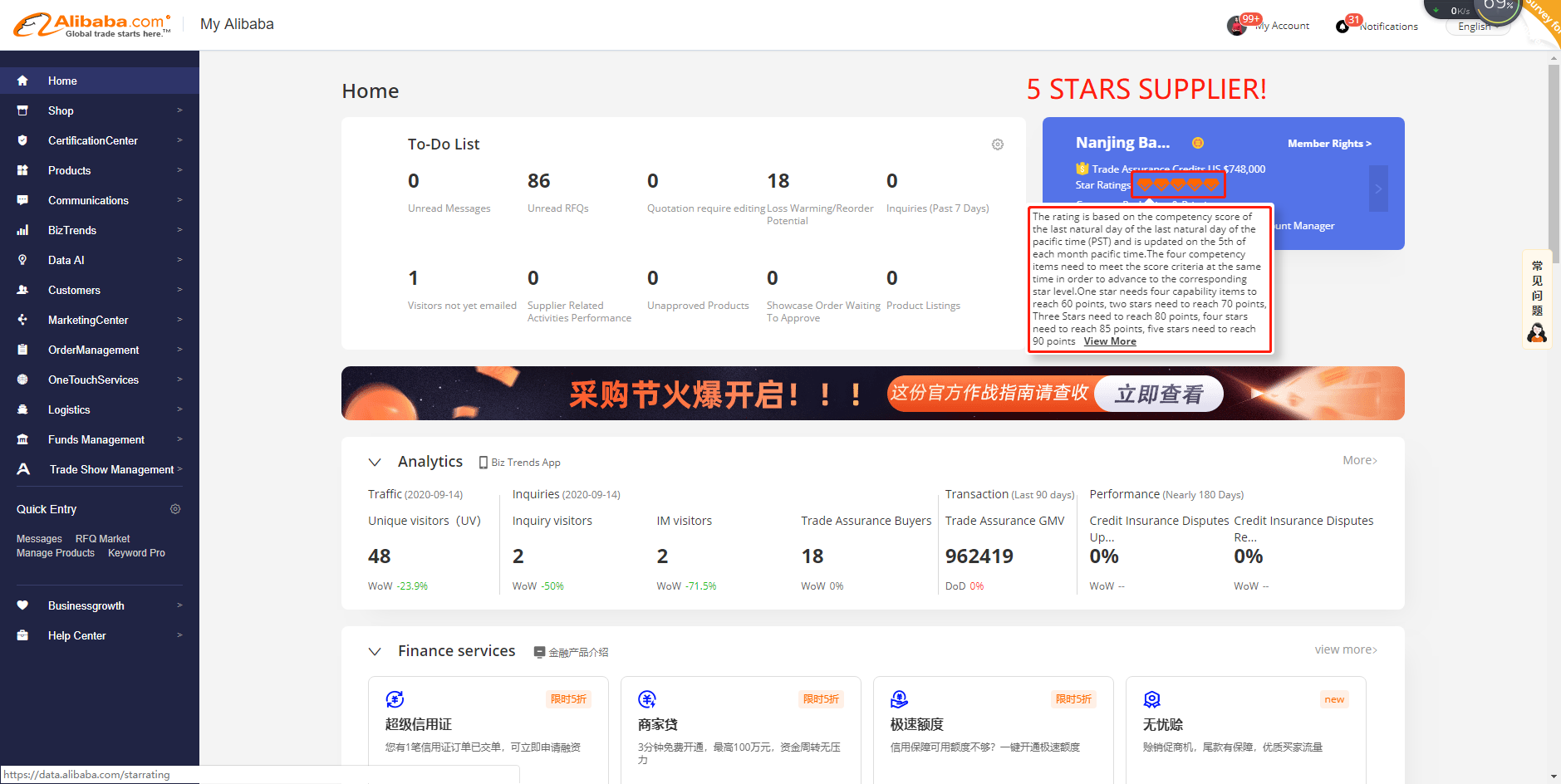

Super Suplier on ALIBABA

How to get Quotation from us?

It's Easy to Order A Correct PHE!

You just need to provide the following information, then we will do the rest things for you:

1. Your application.

2. Hot side & cold side inlet/outlet temperaure range value.

3. Hot side & cold side inlet/outlet flow rate range value.

4. Medium name.

Normally we will take 1-2 hours to make quotation for your confirmation.

1. Your application.

2. Hot side & cold side inlet/outlet temperaure range value.

3. Hot side & cold side inlet/outlet flow rate range value.

4. Medium name.

Normally we will take 1-2 hours to make quotation for your confirmation.

We Are Providing All-round Service and Support!

Every one of our sales engineers has years of working experience in this industry, and professional trained. No matter from technology or business, they can provide you with reliable support.

We have a strong team of engineers who can provide customers with design, selection and perfect technical support services.

Brief Production Flow

Product Show

FAQ

Q : 1. Can I have a sample ? |

A : Yes, welcome to place sample order to test and check quality.Mixed samples are also OK. |

Q : 2. What is your the lead time for production? |

A : Generally Sample needs 1-3 days,mass production needs 15-30 days,also depands on your request. |

Q : 3. Can you accept mixed batch of different products? |

A : Yes,we can provide different product mix wholesale. |

Q : 4. what payment terms do you accept? |

A :Trade assurance,TT,Western Union. |

Q : 5. what is the warranty for your products? |

A :We provide one year warranty for the products.. |

Q : 6. Are you trading company or manufacturer? |

A :Yes,We are manufacturer.Welcome to visit our factory and check our products. |

Product Categories : [5]Heat Exchanger > Plate heat exchanger

Premium Related Products

Other Products

Hot Products

Oven MotorKonb for Gas StoveCast Iron Pan SupportFour Burners Gas StoveHot Sell Built-in Gas StoveHot Selling Copper Burner Gas StovePopular Gas Cooker, Single Burner with Glass MaterialGlass Single Burner Gas StoveSingle Burner Gas Cooker with Stainless Steel PanelGas Valve&Pressure Reducing ValveStainless Steel Three Burners Gas CookerStainless Steel Double Burner Gas Stove, Desktop, Blue Fireas-Gas Lamp&Camping Light (as-05)Gas Cooker Stove&Cooking Stove (as-02)Gas Burner&Gas BurnerLPG Gas Cylinder&Steel Gas Tank as-LPG-6kga