Cryogenic liquid nitrogen liquid oxygen plant

Product Description

Product Advantage Whatsapp:008618936889762

We are professional Gas generator factory ,we produce Oxygen plant, Nitrogen plant, argon Plant ,hydrogen plant.And we producedifferent models of gas plant, different productivity, different gas purity, different size, to meet your different requirements.

Below is our linquid gas producing plant technical parameter for your checking:

(LN2) Liquid nitrogen yield: | 30NM3/H - 40000NM3/H | ||||||

(LN2) Liquid nitrogen purity: | ≥99.99% | ||||||

(LO2) Liquid oxygen yield: | 30NM3/H - 40000NM3/H | ||||||

(LO2) Liquid oxygen purity: | ≥99.6% | ||||||

(LAr) Liquid argon yield: | 180NM3/H - 1350NM3/H | ||||||

(LAr) Liquid argon purity: | ≤2PPmO2, ≤3PPmN2 | ||||||

Operating pressure: | 0.7MPa - 8.5MPa | ||||||

Project Cases Whatsapp:008618936889762

Advanced Design Computing Software Whatsapp:008618936889762

Aspen Hysys(USA)

* The process thermodynamic calculation was carried out by Aspen Hysys(USA)* The BENDER equation and Peng-Robinsonequation with high precision adapted to air medium are adopted.

* Optimize the flow organization form, reasonably reduce the main condensing liquid level, reduce the temperature difference at the hot end of the plate-fin heat exchanger, so that the energy consumption of the device is reduced to the minimum.

* Optimize the flow organization form, reasonably reduce the main condensing liquid level, reduce the temperature difference at the hot end of the plate-fin heat exchanger, so that the energy consumption of the device is reduced to the minimum.

SmartPlant3D

* Adopt SmartPlant3D for cold box piping design and engineering piping design to optimize piping layout and reduce piping resistance;So that the design cycle is shortened, the precast material site assembly is more accurate.

CAESARII

* The task of stress analysis is to carry out mechanical analysis including stress calculation on the whole plant piping system, so that the analysis results meet the requirements of national standards and specifications, and ensure the safety of the whole plant piping itself and its connected machinery, equipment and civil structures.

* The CAESARII stress analysis is used to carry out the mechanical analysis including the calculation of the stress on the pipe system in the cold box, so as to ensure the safety of the pipe itself and the machinery and equipment connected with it and the civil structure.

* The CAESARII stress analysis is used to carry out the mechanical analysis including the calculation of the stress on the pipe system in the cold box, so as to ensure the safety of the pipe itself and the machinery and equipment connected with it and the civil structure.

* CAESARII stress analysis is used to carry out mechanical analysis including stress calculation on the pipeline system in the cold box to ensure the safety of the pipeline itself and its connected machinery, equipment and civil structures. CAESARII provides users with complete international and domestic common pipe design specifications. The correctness of the calculation results has been widely recognized internationally.And become the industrial stress analysis calculation

UniversalPlantViewer

* Germany advanced view software, can be realized anytime and anywhere mobile phone, IPD and computer synchronous view of drawings, design process, both convenient and safe, so that the work is more convenient, accurate supervision.

3D design software

* American Boray Valve: 200,000 times no leak, reliable performance, durable.

* Aluminum skin and guard bar insulation:Ex-factory pipeline high quality aluminum skin insulation, internal use of high quality slag cotton, once in place, avoid the factory after the insulation.

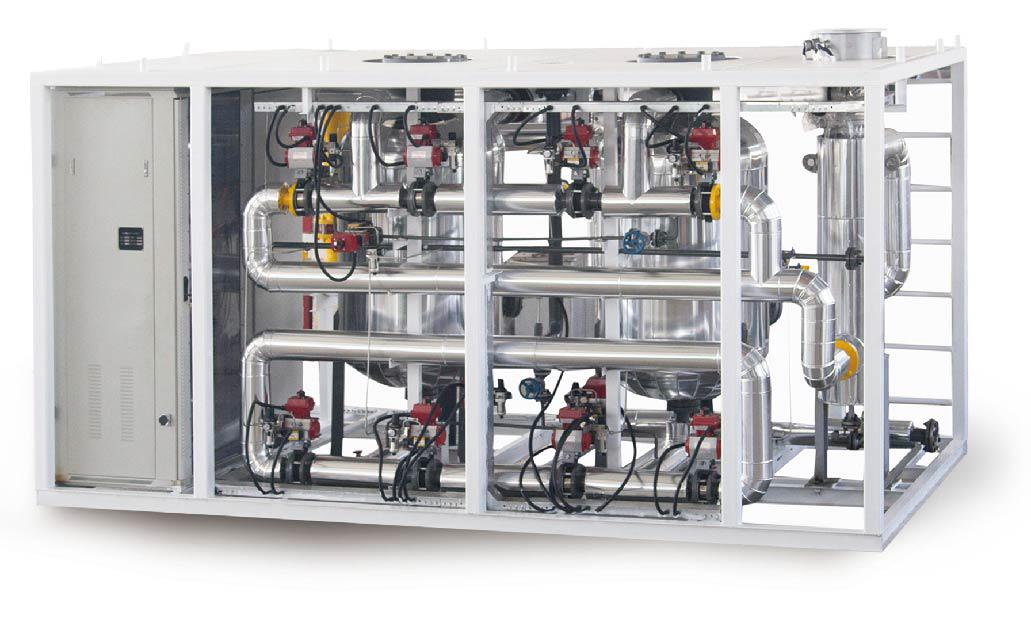

* Electric control cabinet: Modular skid - mounted, electronic display, instrument prefabricated completely.

* Electric control cabinet: Modular skid - mounted, electronic display, instrument prefabricated completely.

ANSYS

* The software has a wealth of physical models, convergence speed and high precision of solution.The distribution of temperature field, pressure field and gas composition inside the research object can be visualized.

Security technology

* Reliable instrument tube protection system

* Pipes are designed along the tower body

* Pipe design along the tower body main condensation evaporator safety design

* Safety setting of oxygen valve

* Molecular sieve anti-punch technology

* Selection and layout of throttle valve

* Pipe design along the tower body main condensation evaporator safety design

* Safety setting of oxygen valve

* Molecular sieve anti-punch technology

* Selection and layout of throttle valve

FAQ Whatsapp:008618936889762

1. Q: Can you provide the drawings of your plant/tanks? |

Normally, our drawings will be provided to our customer only after the order is confirmed. However, we can provide you some drawings which belong to our old customers for reference. By the way, here, I need to remind you that our company only provides the engineering design drawings and the civil design drawings will be out of our range. Because every place has different situation, your side needs to find civil design company in your local market to do the drawings according to your specified environment. |

2. Q: How’s the producing time and delivery time?? |

Normally, our production time is 6 months for air separation plants but it also depends on the capacity you require. The bigger the plant, the longer time for production. Please also note that when the plant is finished, we need to wait for bulk vessel. It’s very common to wait for one or two months to find the right vessel. The delivery date is 3-5 months. |

3. Q: What about warranty? |

Equipment warranty is 12 months from the date on which the equipment is applied successfully into operation, or 14 months from the date on which the equipment has been delivered, whichever comes first. Generally speaking, our air separation unit can work normally for 15-20 years if it is maintained properly. As a leading brand in China with over 40 years history, reliability and stability of our ASU is much better than small young companies. |

More Products Whatsapp:008618936889762

PSA gas plant Gas compressor Gas Cylinder Gas Regulator

Product Categories : [2]Gas plant > Liquid oxygen plant

Premium Related Products

Other Products

Hot Products

Oven MotorKonb for Gas StoveCast Iron Pan SupportFour Burners Gas StoveHot Sell Built-in Gas StoveHot Selling Copper Burner Gas StovePopular Gas Cooker, Single Burner with Glass MaterialGlass Single Burner Gas StoveSingle Burner Gas Cooker with Stainless Steel PanelGas Valve&Pressure Reducing ValveStainless Steel Three Burners Gas CookerStainless Steel Double Burner Gas Stove, Desktop, Blue Fireas-Gas Lamp&Camping Light (as-05)Gas Cooker Stove&Cooking Stove (as-02)Gas Burner&Gas BurnerLPG Gas Cylinder&Steel Gas Tank as-LPG-6kga